Medical device and MedTech insights, news, tips and more

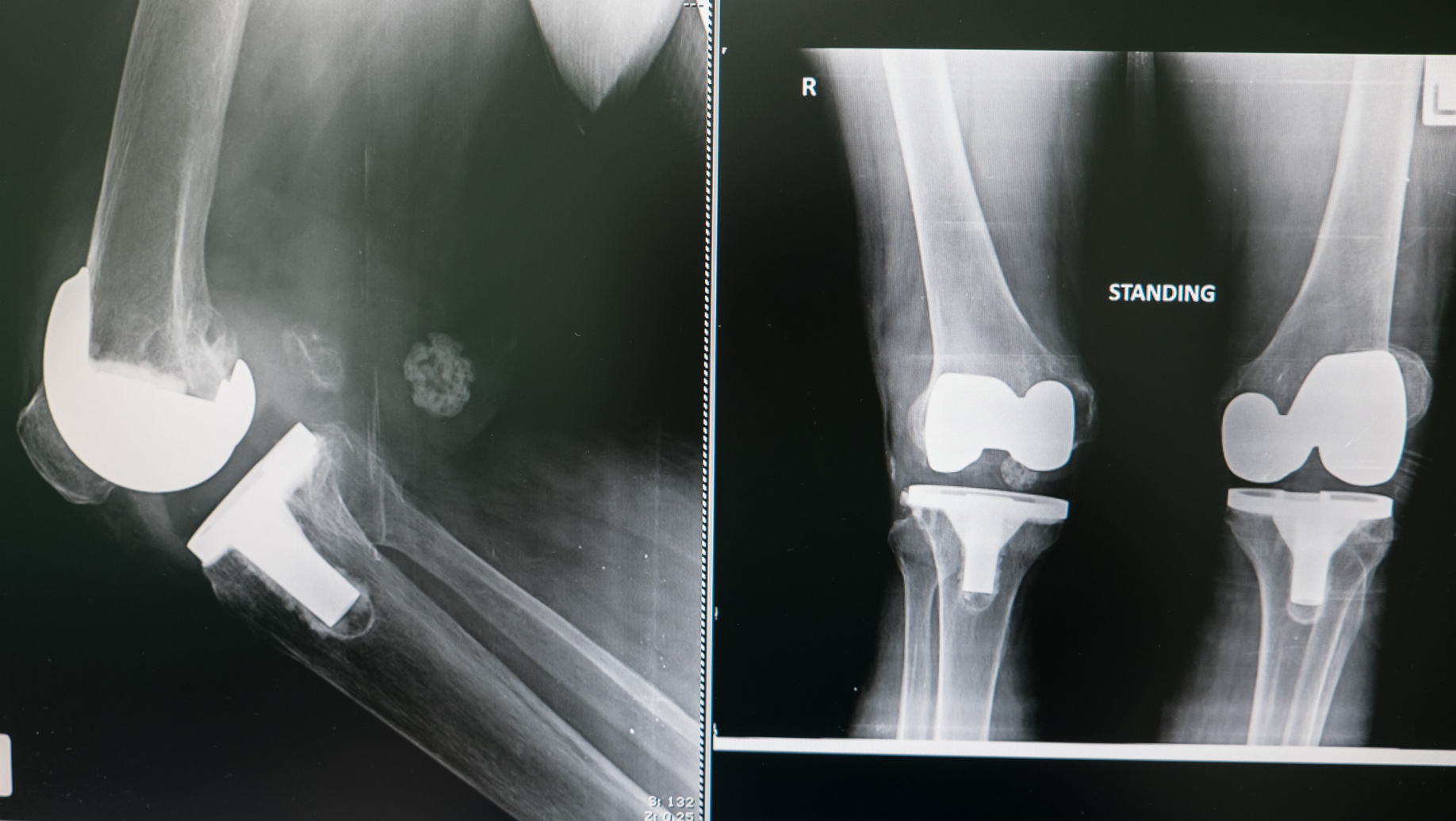

A slick way to test artificial hip and knee joints

May 25, 2016

A new study suggests that natural proteins can be used to effectively test new replacement hip and knee joints in the laboratory. The work could help with improving design in order to reduce wear and tear and increase the lifespan of such prosthetics. Details are reported this week in the International Journal of Surface Science and Engineering.

Belinda Pingguan-Murphy and Subir Ghosh of the University of Malaya, Malaysia, and Dipankar Choudhury of Brno University of Technology, Czech Republic, explain that albumin and globulin proteins are the predominant protein components of the synovial fluid which surround healthy joints. Albumin is also the main protein component of egg white and blood plasma. The proteins are also found in the fluid held around our joints by the synovial membrane. They play important roles in the lubrication mechanism of our joints.

The selection of materials for the prosthesis head and cup of a replacement joint relies on the mechanical and surface properties of the materials chosen and how well they take aboard the natural lubricating proteins. Advanced joints use ultra high molecular weight polyethylene (UHMWPE) because it is not only flexible but is also resistant to wear. UHMWPE also repels water, it is hydrophobic and this is usually coupled with a ceramic component which is the opposite, hydrophilic, and so makes a perfect sliding partner for least friction.

However, there is always room for improvement in terms of lowering friction and making a prosthetic joint move even more smoothly as well as in terms of extending the lifespan of a joint. Such improvements would give patients a better quality of life as well as extending the time between prosthetic surgery if a repeat procedure is even an option.

Read More – Source: A slick way to test artificial knees and hips – Iconic Science